This post may contain affiliate links. Please read our disclosure for more information.

There’s no Dave Ramsey of scrap-metal welding. In other words, I can’t fire up my Kindle and download The Seven Baby Steps to Building Your First Lifesize Bison out of Scrap Metal.

Aside from the John Lopez video below, I’m basically on my own. Just me and whatever critical-thinking skills I have left from nine years of higher education completed last century.

But this John Lopez video is enough to get me started. My first task is to emulate John and create a bison frame/skeleton with an accompanying bison silhouette.

Easy-peasy, right? Wrong. The first week of my bison build wasn’t exactly my finest hour. Let’s see why.

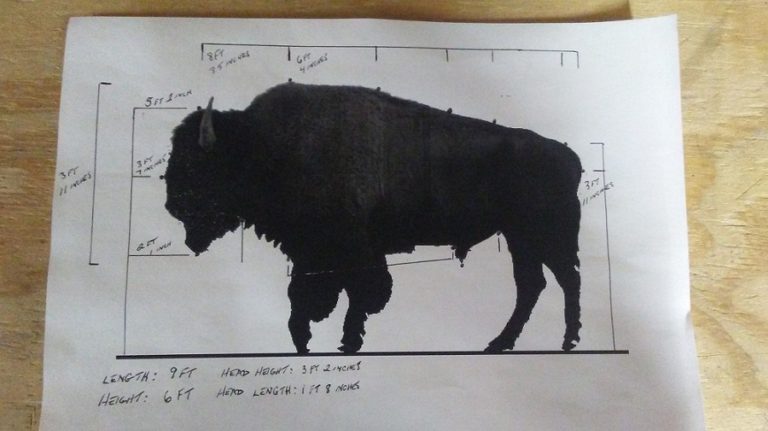

The week started off promising. I downloaded a side view of a wild bison, photoshopped it to create a silhouette template, and then calculated the corresponding dimensions of a lifesize bison. Here’s a picture of my silhouette template.

The next step, of course, was to get the metal to create the frame and silhouette. But before I purchased the metal, I had to consider some pretty formidable limitations. I don’t have anything close to a real metal fabrication shop. I have an entry-level stick welding machine (Hobart 160i Stickmate) and an entry-level angle grinder (Porter Cable). That’s it. No chop saw, plasma cutter, or oxyacetylene torch—my shop is pitifully devoid of anything capable of cutting and bending heavy-duty metal. So with these limitations in mind, then, I went online and ordered 22-gauge sheet metal and piping from Lowe’s and a pair of sheet-metal shears from Harbor Freight.

And then I did some research on stick welding thin metal. Talk about putting the proverbial horse before the proverbial cart! The consensus of the online pros was that welding anything thinner than 16-gauge was a bridge too far for stick. My Lowe’s metal order was thus a major screw-up. As soon as it arrived, I returned it.

The only good thing about this major screw-up was that it forced me to find a better metal supplier. Lowe’s metal offerings were quite limited. I couldn’t find anything thicker than 22-gauge. The supplier I found in Raleigh, however, had a much more robust selection. I was able to get the same quantity of metal at the thicker gauge (i.e., 16-gauge) and the cost was a third less than Lowe’s.

“Okay,” I said to myself. “I got the right metal. Let’s build me a bison frame and silhouette.”

Not so fast. I had the right metal. I didn’t have the right welding rods.

I have 7018 welding rods. Below is a picture of a bead from a 7018 rod connecting two pieces of 14-gauge metal. Hardly a thing of beauty, but pretty good for a novice welder.

And here’s what welding two pieces of 16-gauge metal looks like with the same rod. Ouch. Is that ugly or what!

It turns out the 7018 rod runs too hot for 16-gauge metal. What I need to use are 6013 rods.

Dutifully humbled by the welding gods again, I went back online and ordered some 6013 rods. They should arrive early next week.

Final Thoughts

Okay, groovy freedomist, that’s all I got. I was hoping to have a glorious bison frame and silhouette for you today, but my vast welding ignorance conspired against me. Have a great weekend. Peace.

Man! This is tough work! Let’s leave easy this seems harder af. I am an ameture, maybe that’s why I’m sounding like this. #RESPECT for you. You are an artist. PEACE

I’m impressed Mr. Groovy with the ambitious project you’ve undertaken! I’ve done a little MIG welding on projects around the house and it’s not as easy as it looks. I’m sure it’s going to look great and looking forward to your progress.

Shannon Henry recently posted…Bulletproof Your Future and Avoid Forced Retirement

It’s going to fun to hear your updates! Refreshing that I’m not the only one who jumps into a project only to find out I have some learning to do. Keep us posted with your progress (and your set backs too!).

Mr. P2F recently posted…Don’t make a million dollar mistake with your future

What has my life come to…how did I turn into the type of person who gets up on a Monday morning and reads about someone building a metal bison? And why am I waiting for the next installment to come out?🤣

David @iretiredyoung recently posted…Early retired lifestyle post for this week

You’re a twisted soul, my friend. But I completely understand. A life without weird amusements is a life without fun.

Let the bison building commence. Can not wait to see the final product! Great seeing you guys the other week.

Mrs.Wow recently posted…You’re Average, So Am I

Thank you, Mrs. WoW. And don’t for a minute think I forgot all about your wonderful visit. I’ll be embarrassing you this Friday. Stay tuned.

It will be great to see this challenging project come to fruition! I’m enjoying seeing the planning going on behind its artistic creation.

Thank you, RD. And you are so right about the “planning going on behind [an] artistic creation.” If you want to hone your critical-thinking skills, just try to create something. It’s amazing what the mind has to do in order to make a vision a reality.

Nice work! We have a lot of bison decor since we live in Wyoming now. I like seeing all the creative things you’re up to in early retirement!

I’m jealous, Kim. Mrs. Groovy and I have only been to Wyoming once, but we could definitely see ourselves living there. So beautiful. And you don’t have to drive far to see a bison!

You are a true inspiration, taking on a project of this magnitude. Not only are you well-read, articulate and thoughtful, you aren’t afraid to manhandle steel until it looks like a freaking bison!

“I’m Mr. Groovy. I’m making a bison. You got a f#*king problem with that??!”

I am looking forward to watching your progress.

“You are a true inspiration, taking on a project of this magnitude. Not only are you well-read, articulate and thoughtful, you aren’t afraid to manhandle steel until it looks like a freaking bison!”

I accept all superlatives! I can’t tell how much your thoughts made my day. You’re the best, my friend. Thank you.

What an ambitious project! I think it shows that with some perseverance, patience and at least some basic skill, anyone can set out to accomplish what their heart tells them to do. You may have some ups and downs and the end result might not resemble what you set out to do but the journey is as important as the destination. This applies not only to one’s artistic endeavors but also their financial and other life goals. Looking forward to seeing your completed bison, or whatever else it turns into!

“You may have some ups and downs and the end result might not resemble what you set out to do but the journey is as important as the destination.”

Nailed it, Pat. Thank you.